A lot of progress has been made inside the EAF building. The furnace is in place and the vault that will house the EAF transformer is under construction.

Below is a picture of the new and extended rounds caster cooling bed. Proper cooling is critical for the dimensional quality of the rounds that we will provide to our seamless pipe mills. This section of the cooling bed is elevated to allow more cooling air to the rounds. A bloom elevator is being installed to transport the rounds from the current cooling bed to the new area. Stay tuned for updates on the elevator!

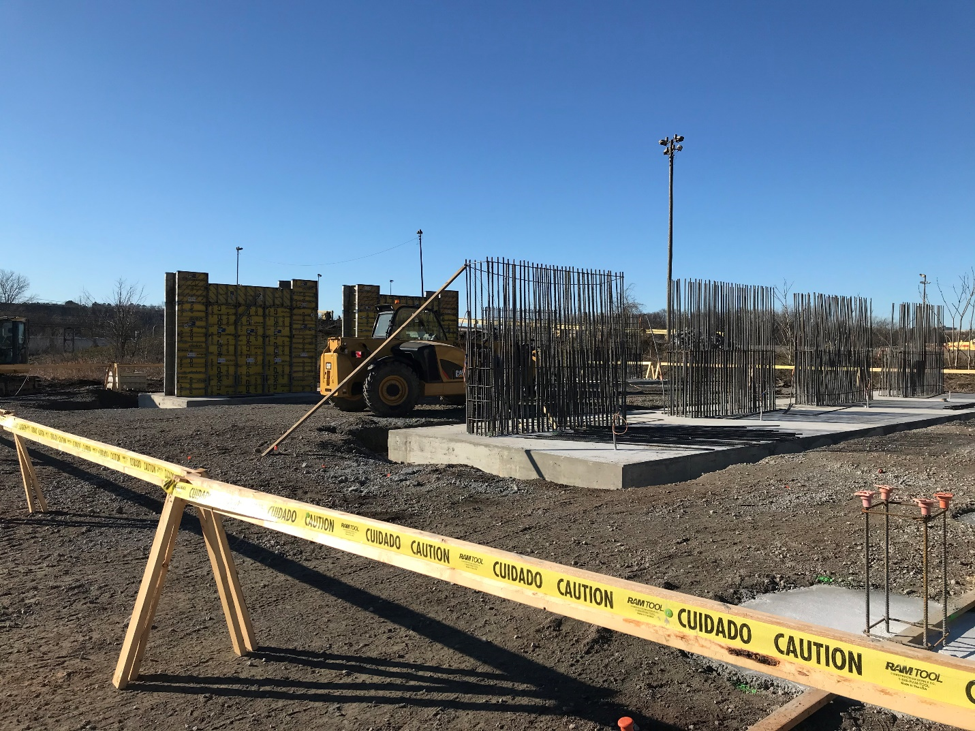

Construction on our Air Separation Unit (ASU) plant has commenced. Below is a picture of the civil construction and concrete work that is ongoing. This will be a state-of the-art plant to provide the operations with oxygen, nitrogen and argon. Oxygen is used in the melting process directly providing additional energy along with natural gas. The argon will be used primarily at the EAF to prevent re-oxidation of the steel and to stir the steel during processing in the ladle.

Construction is going strong and commissioning will be starting soon. It won’t be long until the shop has molten steel and new high-quality rounds are produced!

Made in the U.S.A. for more than 100 years

Made in the U.S.A. for more than 100 years